Rubber Flexible Joint Introduction

Rubber Flexible Joint

Advantages of China Valve Manufacturing Co., Ltd. Rubber Flexible Joint

Vibration And Noise Reduction

forede ® Rubber flexible joints have excellent shock-absorbing capabilities. They can absorb vibrations caused by fluid flow, machinery, or ground movement, which reduces noise and stress on the entire piping system.

Media Resistance And Weather Resistance

forede ® rubber flexible joint has good media resistance and weather resistance, and can work stably under different media and climatic conditions. For example, it can be used in high temperature, low temperature, acid and alkali environments, and has high corrosion resistance and oil resistance.

Easy Installation

forede ® rubber flexible joint has various installation methods, including loose flange, fixed flange and threaded, which are suitable for various pipeline systems. Its design makes the installation process simple and fast, and can solve the problems of pipeline jack deviation and axial expansion.

Wide Range Of Application

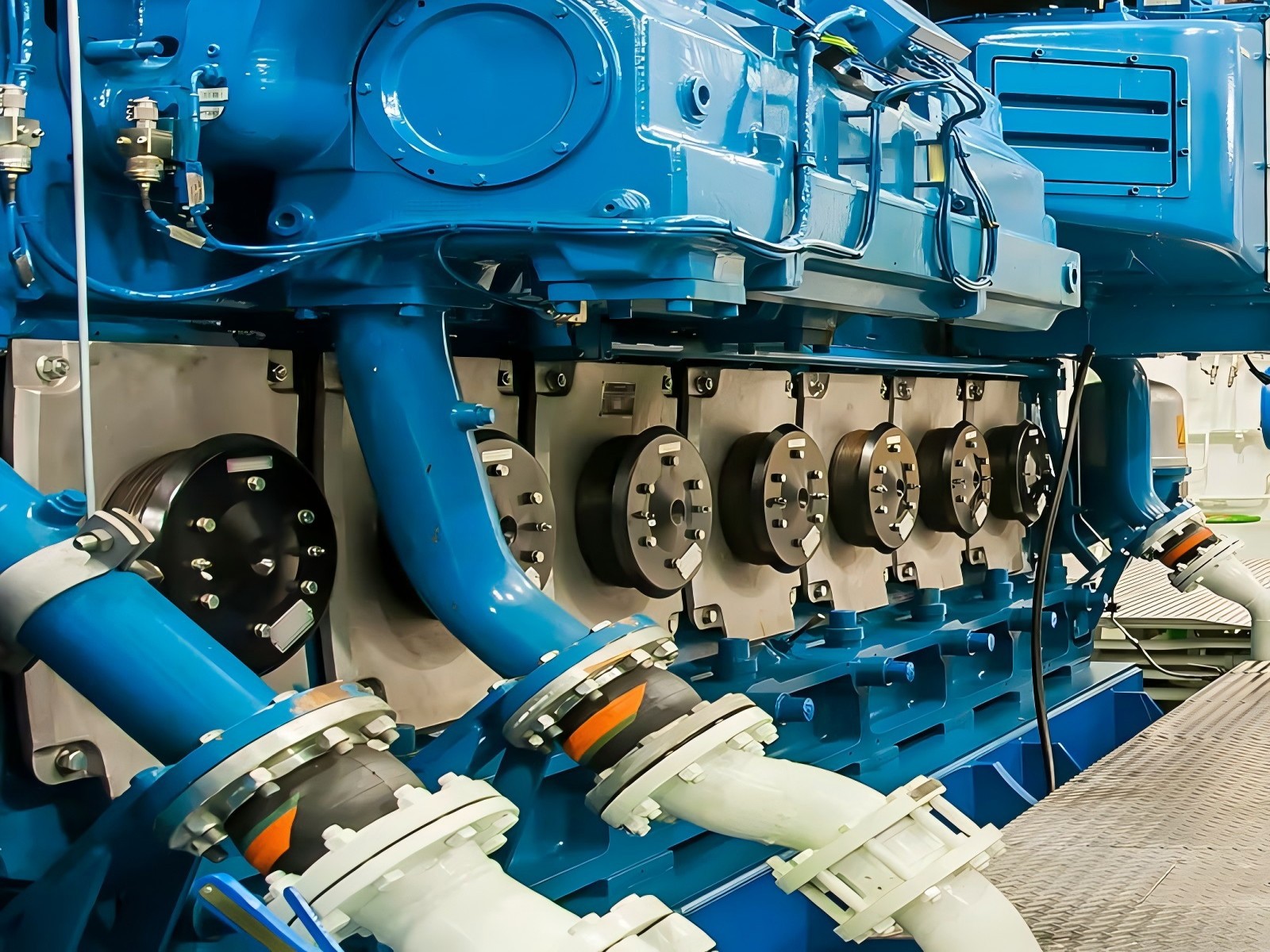

forede ® Rubber flexible joints are widely used in water, electricity, chemical industry, ship mooring system and other fields, suitable for various pipeline systems.

Rubber Flexible Joint application

Rubber Flexible Joint For Chemical

Rubber flexible joints for chemical applications are an essential component in the safe and efficient transportation of chemicals from one location to another. These joints are designed to provide a flexible connection between two pipework systems, allowing for movement and expansion caused by changes in temperature, pressure, or vibration.

One of the primary advantages of rubber flexible joints is their ability to absorb vibrations, which reduces stress on the pipework. This results in a longer lifespan for both the pipework and the joints themselves. Additionally, they are resistant to a wide range of chemical substances, making them an ideal choice for handling almost any chemical application.

Rubber flexible joints are also easy to install and maintain, requiring minimal maintenance over their lifespan. They are available in a range of sizes and configurations, ensuring that they can be easily integrated into any chemical pipework system.

Rubber Flexible Joint For petroleum

Rubber flexible joints are essential components in petroleum industries. These joints are designed to provide a high degree of flexibility in piping systems, allowing for movement and vibration to occur without interruption to the line. They are widely used to connect piping, pumps, valves, and other equipment, ensuring the safe and efficient transport of petroleum products.

One of the main advantages of rubber flexible joints is their ability to absorb vibration and prevent damage to the piping system. This is particularly important in the petroleum industry, where pipelines are exposed to a range of external influences that can cause unwanted movement and vibration. The rubber material used in flexible joints is highly resistant to corrosion, abrasion, and chemicals, making it an ideal choice for use in harsh environments.

Another benefit of rubber flexible joints is their ability to handle high pressures and temperatures. Some pipelines in the petroleum industry operate at extremely high pressures and temperatures, and rubber flexible joints have been engineered to withstand these conditions while maintaining their integrity. This ensures that the risk of pipeline failure is greatly reduced, promoting a safer and more reliable system.

Rubber Flexible Joint For marine fire-fighting pipes

Rubber Flexible Joints are an integral component of marine fire-fighting pipes. These joints provide flexibility and support to the pipes in the event of a fire emergency. They are designed to withstand high temperatures, pressure, and chemical exposure.

The rubber material used in flexible joints is of high quality and is resistant to deteriorating factors such as ozone, UV radiation, and extreme weather conditions. These joints are also capable of absorbing vibration and shock, which allows for a more stable and safe piping system.

In addition to their safety functions, rubber flexible joints are easy to install and maintain. This makes them ideal for use in marine fire-fighting systems where quick response times are critical. The joints are also highly durable and offer a long lifespan, reducing the need for frequent replacements and costly repairs.

Rubber Flexible Joint For sewage treatment pipes

Rubber flexible joints for sewage treatment pipes are an essential component that provides flexibility and elasticity to the piping system. These joints are designed to absorb the stress and vibrations that occur within the pipes during operation, reducing the risk of cracks and leaks. They are an essential component in sewage treatment plants, where the pipes are required to withstand high pressures and corrosive substances.

One of the most significant advantages of rubber flexible joints is their durability and longevity. The high-quality rubber used in manufacturing these joints is resistant to wear and tear, making them last longer and require minimal maintenance. Such joints can withstand extreme temperatures, humidity, and corrosive substances, ensuring high performance and extended service life.

Another benefit of using rubber flexible joints for sewage treatment pipes is that they can be used in a variety of applications and environments. These joints are designed to fit pipes of different sizes and configurations, making them suitable for use in various sewage treatment plants. They can also withstand water hammer and provide effective noise reduction, ensuring a smooth and quiet operation.

We're well-known as one of the leading y strainers manufacturers and suppliers in China for our quality products and good service. Please feel free to wholesale y strainers at competitive price from our factory. Contact us for more details.

Fognail, DN20 K202 Fire Sprinkler Heads, Horizontal Fire Foam Tank