Butterfly Valves Introduction

Butterfly Valves

Advantages of China Valve Manufacturing Co., Ltd. Butterfly Valves

Low Pressure Drop

One of the biggest advantages of forede ® butterfly valves is their low-pressure drop. This means that the valve maintains constant pressure across the entire operation, even when the valve is closed, making it ideal for flow control in applications where pressure loss is a concern.

Versatile

forede ® Butterfly valves are highly versatile and can be used in a wide variety of applications across many industries, from the petrochemical industry to water treatment facilities. Additionally, they can be used in both high and low-pressure systems, making them an excellent choice for applications in which the pressure must remain constant.

Small Opening And Closing Torque

Since the butterfly plates on both sides of the shaft are acted upon by the medium in basically the same way, and the torques generated are in opposite directions, opening and closing is easier.

Easy to Operate

forede ® Butterfly valves are incredibly easy to operate, requiring only a simple quarter turn of the handle to open or close the valve. This makes them ideal for applications where quick and easy flow control is necessary, saving time and effort.

-

D81-16Q Handle groove butterfly valveProduct Usage Grooved handle butterfly valve not only has good sealing performance, but also has the quickness required for connection with pipe fittings. The handle of the groov...read more

-

D381X-16Q Grooved Type Gear Butterfly ValveProduct Usage In the fully open position, the thickness of the disc is the only resistance when the medium flows through the valve body, so the pressure drop generated by the val...read more

-

D71X-16Q Wafer Gear Type Butterfly ValveProduct Usage It is a kind of rubber sealing butterfly valve, which is widely used in drainage pipeline systems of electric power, water conservancy, chemical industry, constructio...read more

-

D371X-16Q Wafer Gear Type Butterfly ValveProduct Usage Wafer-type gear butterfly valve is a kind of rubber-sealed butterfly valve, which is widely used in water supply and drainage of water plants, power plants, steel mi...read more

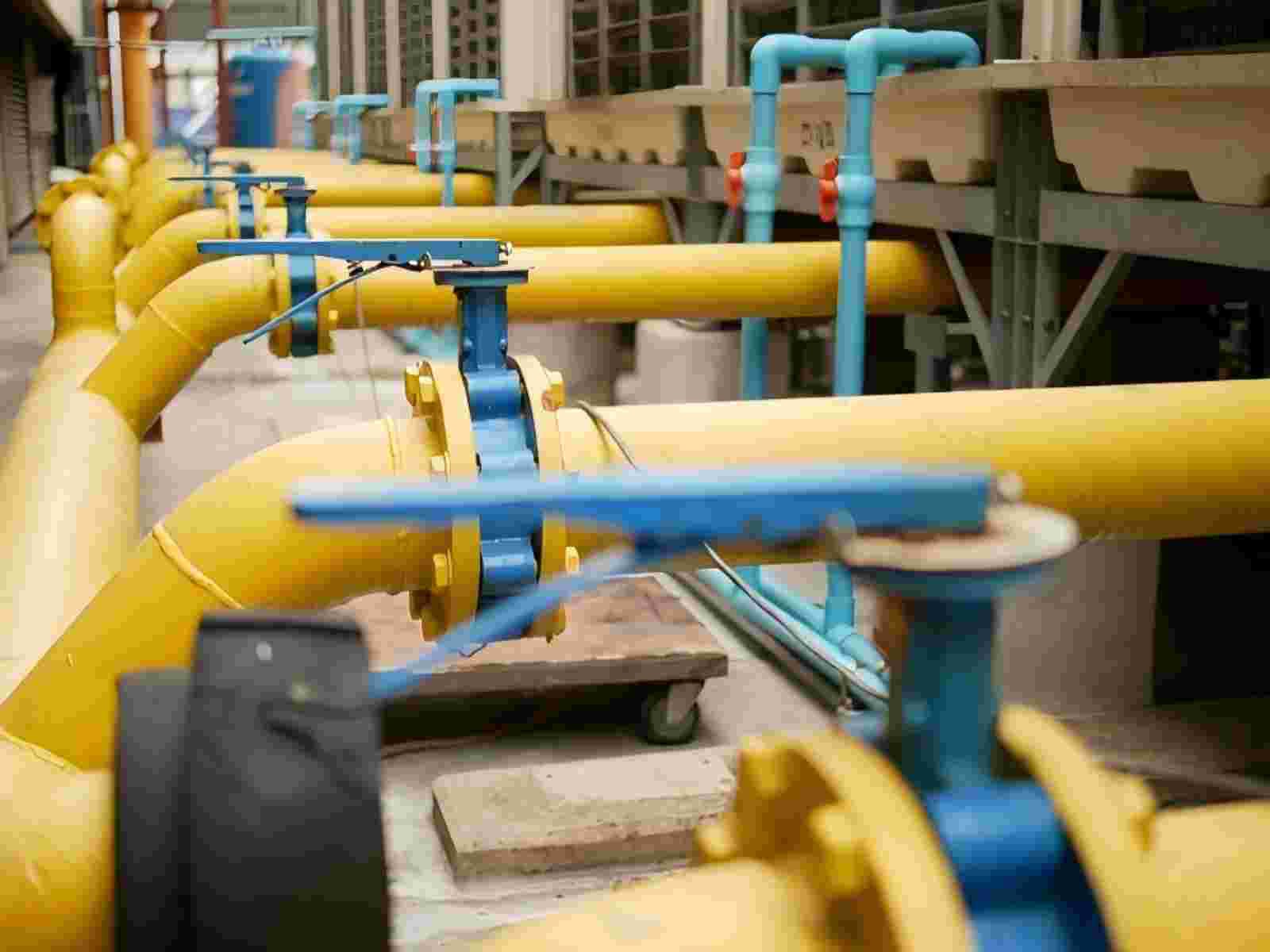

Butterfly Valves Application

Butterfly Valves For Oil Industry

Butterfly valves play a vital role in the oil industry, serving as a crucial component in the transportation and processing of oil. These valves are widely used in pipelines, tanks, and refineries, and they provide excellent control over the flow of oil and other fluids.

Butterfly valves are designed to be lightweight and compact, making them easy to install and operate. With just a simple quarter-turn of the valve, operators can easily open or close the valve, allowing for precise control over the flow of oil. This is especially important in refining processes, where precise control is critical to ensure the quality and consistency of the final product.

Another advantage of butterfly valves in the oil industry is their ability to handle large volumes of fluid. These valves can be designed to accommodate large diameters, making them ideal for use in pipelines and processing plants where high volumes of oil are processed every day. Additionally, butterfly valves are highly resistant to wear and corrosion, which is especially important in harsh environments where exposure to extreme temperatures, chemicals, and other contaminants can cause damage to standard valves.

Butterfly Valves For Chemical Industry

Butterfly valves are essential components in many industries, and the chemical industry is no exception. One of the main advantages of butterfly valves is their durability and ability to handle high temperatures and pressure levels. This makes them ideal for use in the chemical industry, where corrosive and abrasive materials are often present.

In the chemical industry, butterfly valves are commonly used to control the flow of liquids and gases through pipes and other equipment. They are often used to regulate the flow of chemicals between different stages of a production process or to isolate equipment for maintenance or repair. Because they are made of high-quality materials such as stainless steel or PVC, butterfly valves are able to withstand the harsh conditions of many chemical processes, including high temperatures, corrosive substances and extreme pressure levels.

In addition to their durability and reliability, butterfly valves are also cost-effective and environmentally friendly. They consume less energy than other types of valves, which lowers the operating costs of chemical plants and reduces their environmental impact. The use of butterfly valves also helps to reduce the amount of waste generated during production, as they can be easily cleaned and reused.

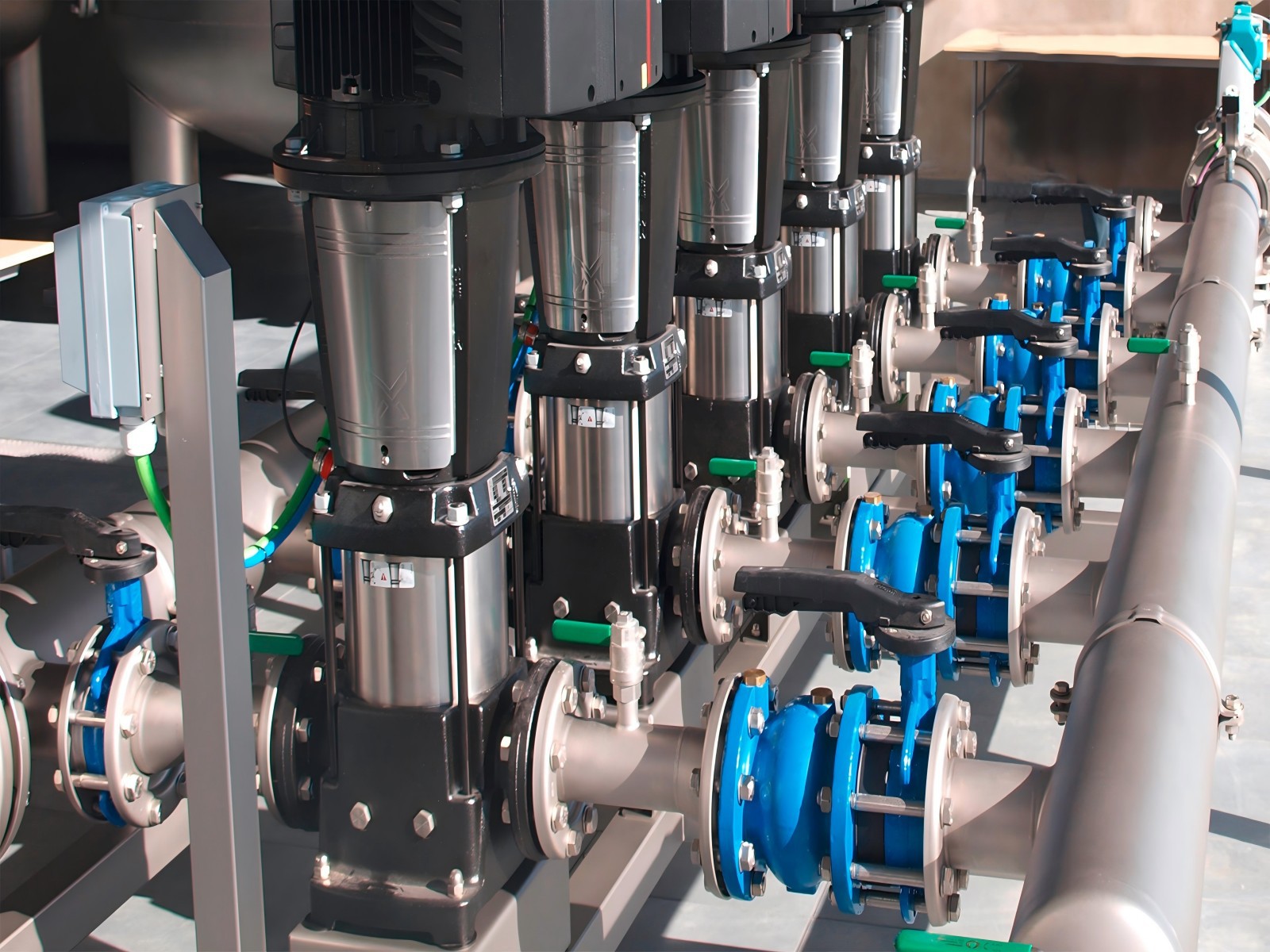

Butterfly Valves For Water treatment

Butterfly valves have been widely used in water treatment applications due to their numerous advantages over other valve types. These valves are lightweight, easy to install, and require minimal maintenance. They also provide high flow rates and excellent control over the flow of water.

One of the main benefits of butterfly valves is their compact design. They consist of a disc that rotates around a stem to control the flow of water. This design requires less space compared to other valve types, making them ideal for use in applications with limited space.

Butterfly valves also provide excellent control over the flow of water. They can be easily adjusted to regulate the flow rate according to the specific needs of the application. This makes them ideal for use in water treatment applications where precise flow control is necessary for optimal performance.

Butterfly Valves For Power Industry

As a critical component of the power industry, butterfly valves play an important role in regulating and controlling the flow of fluids and gases through power plants and related facilities. These valves are known for their durability, versatility, and ease of use, making them a popular choice among engineers and operators in the power sector.

Butterfly valves are typically made up of a circular disc that rotates around an axis perpendicular to the fluid flow, allowing for precise control of the flow rate. They are often used in applications where reliable, low-maintenance operation is essential, such as in power generation plants where they are installed in systems such as cooling water, air, and gas.

One of the main advantages of butterfly valves is their compact design, which allows them to be easily installed in tight spaces. They also offer a wide range of choices when it comes to materials and sealing designs, providing flexibility in selecting the most appropriate valve for specific applications. Some of the most commonly used materials for butterfly valves in the power industry include stainless steel, ductile iron, and carbon steel.

We're well-known as one of the leading butterfly valves manufacturers and suppliers in China for our quality products and good service. Please feel free to wholesale butterfly valves at competitive price from our factory. Contact us for more details.